Imagine if you’re in the heart of a bustling factory, where machines hum, workers move with purpose, and the air is thick with the sounds of industry. Now, envision a small spark from an overheated machine or a spill of flammable liquid that quickly turns into a raging fire. In such environments, the right fire safety equipment isn’t just a regulatory requirement – it’s a lifeline.

Fire safety in factories and manufacturing plants is crucial, given the complex machinery, flammable materials, and heavy electrical use. Choosing the appropriate fire safety equipment can be the difference maker between a minor incident and a major disaster. This article will walk you through the process of selecting and maintaining fire safety gear tailored to the unique needs of your factory.

Fire Hazards in Factories

Factories are unique in their operations and risks, making it essential to understand the specific fire hazards they pose. Let’s delve into some common fire risks in these environments and how they can impact safety.

Flammable Liquids and Gases

In many factories, the production processes involve flammable liquids and gases. Think about solvents, fuels, and chemicals that are integral to your operations. These materials can ignite easily if not properly stored or handled. Picture a can of solvent tipping over near a hot surface; the potential for disaster is immediate and severe. Using specialized storage cabinets and adhering to strict handling protocols can prevent such scenarios from escalating.

Electrical Equipment

Factories are powerhouses of electrical activity. From the smallest widget to the largest machine, electricity is at the core of operations. However, with great power comes great responsibility. Faulty wiring, overloaded circuits, or neglected machinery can lead to dangerous electrical fires. Regular inspections and maintaining your equipment can significantly reduce these risks. Imagine the peace of mind knowing that every wire and circuit in your factory is safe and sound.

Dust and Fibers

If your factory deals with materials like wood, textiles, or metals, you know how quickly dust can accumulate. This seemingly harmless dust can become a ticking time bomb, especially in confined spaces where it can easily ignite. Effective dust control systems and thorough housekeeping routines are crucial. Picture your factory’s air clear and safe, free from the hazards of combustible dust.

Machinery

Heavy machinery is the backbone of manufacturing, but it can also be a significant fire hazard. Overheating parts, friction, and mechanical failures can all lead to fires. Regular maintenance and having automatic shut-off systems in place are key to preventing these incidents. Imagine your machines operating smoothly without the risk of sparking a fire due to overheating.

The Lifesaving Benefits of Industrial-Grade Fire Safety Equipment

Investing in top-notch fire safety equipment is more than a legal requirement—it’s an investment in your workforce’s safety and the longevity of your operations. Here’s why it’s so important:

Protecting Lives

The most compelling reason to invest in fire safety is the well-being of your employees. In the chaos of a fire, quick access to the right equipment can be the difference between safety and catastrophe. Imagine your team, well-trained and equipped, calmly and efficiently handling a fire emergency, ensuring everyone’s safe escape.

Safeguarding Your Facility

Fires can devastate your factory, causing irreparable damage to machinery, inventory, and infrastructure. Effective fire safety measures can help contain and extinguish fires quickly, preserving your assets and keeping production lines running. Picture a scenario where a fire is swiftly controlled, and your operations are back on track with minimal disruption.

Ensuring Compliance

The fire safety regulations are not just about avoiding fines—they are about demonstrating a commitment to safety and responsibility. Compliance with fire safety standards helps build a culture of safety and can prevent costly legal issues. Imagine your factory as a model of safety and compliance, earning respect and trust from employees and stakeholders alike.

Maintaining Business Continuity

A significant fire can bring production to a halt, disrupt supply chains, and tarnish your reputation. Having robust fire safety equipment and plans ensures your business can recover quickly and continue operations with minimal downtime. Picture a resilient operation that can bounce back swiftly from any fire-related incident.

Selecting the Right Fire Safety Equipment

Choosing the right fire safety equipment is about understanding your factory’s unique risks and needs. Let’s explore the various types of equipment available and how to select the best options for your environment.

Fire Extinguishers

Fire extinguishers are your first line of defense against small fires. Different types are designed for various fire classes:

- Class A: For fires involving ordinary combustibles like wood and paper.

- Class B: For flammable liquids such as oil and gasoline.

- Class C: For electrical generated fires.

- Class D: For combustible metals.

- Class K: For fires caused by cooking oils and fats.

Ensure your factory is equipped with the appropriate types of extinguishers based on the materials and processes you use. Regularly train your staff on how to use them effectively. Picture a workforce that knows exactly how to tackle a small fire before it escalates.

Fire Suppression Systems

For more complex or large-scale fire risks, automatic fire suppression systems are essential. These systems detect and control fires without human intervention. Options include:

- Sprinkler Systems: Suitable for general fire hazards.

- Foam Systems: Effective for flammable liquid fires.

- Gas Systems: Ideal for environments where water damage must be avoided.

- Dry Chemical Systems: Versatile for various fire types.

Consider consulting with fire safety professionals to determine the best system for your specific needs. Imagine a state-of-the-art system that activates at the first sign of trouble, keeping fires under control before they can cause significant damage.

Fire Detection and Alarm Systems

Early detection is crucial in preventing fire escalation. Fire detection systems can include:

- Smoke Detectors: Alert you when there is smoke.

- Heat Detectors: Trigger alarms when temperatures rise rapidly.

- Flame Detectors: Use optical sensors to detect flames.

- Gas Detectors: Monitor for the presence of flammable gases.

These systems should be integrated with audible alarms and communication systems to ensure a swift response and evacuation. Picture a system that senses danger and alerts everyone instantly, giving precious time to respond and evacuate.

Fire Doors and Barriers

Fire doors and barriers are designed to contain fires and prevent them from spreading. They are crucial for creating safe evacuation routes and protecting critical infrastructure.

- Fire Doors: Designed to withstand fire and provide safe egress.

- Fire Barriers: Walls, floors, and ceilings that prevent fire spread.

Ensure these barriers are strategically placed and maintained. Picture a well-designed facility where fire can’t easily spread, giving everyone more time to reach safety.

Emergency Lighting and Signage

In the chaos of a fire, power outages are common, making visibility a challenge. Emergency lighting and clear signage are essential for guiding employees to safety.

- Exit Signs: Clearly mark all escape routes.

- Emergency Lights: Illuminate paths during power failures.

Personal Protective Equipment (PPE)

For high-risk areas, personal protective equipment can be a crucial line of defense. This might include:

- Fire-Resistant Clothing: Protects against heat and flames.

- Respirators: Guard against inhaling smoke and toxic fumes.

- Protective Gloves and Boots: Shield from burns and heat.

Ensure all PPE meets safety standards and that your employees are trained in its use. Picture your team, equipped with the best gear, confidently navigating through a fire emergency.

Maintenance and Training: The Cornerstones of Fire Safety

Having the right equipment is only part of the solution. Regular maintenance and thorough training are essential to ensure your fire safety measures are always ready.

Regular Inspections and Maintenance

Fire safety equipment must be regularly inspected and maintained to ensure it functions correctly when needed. This includes:

- Checking the pressure and condition of fire extinguishers.

- Testing and servicing fire suppression systems.

- Inspecting and cleaning detection systems.

- Ensuring fire doors and barriers are operational and unobstructed.

Establish a regular maintenance schedule and record of all inspections. Picture a routine where every piece of equipment is in top shape, ready to perform at a moment’s notice.

Employee Training and Drills

Employees should be well-versed in the use of fire safety equipment and emergency procedures. Regular training sessions and fire drills are essential. Training should cover:

- Operating fire extinguishers and other equipment.

- Emergency evacuation procedures.

- Understanding fire alarms and signals.

- Proper use of personal protective equipment.

Time-to-time drills ensure that everyone knows their role and can respond quickly in an emergency. Picture a workforce that’s confident, prepared, and unflappable in the face of a fire.

Final Thoughts

Choosing the right fire safety equipment for your factory is about more than just ticking boxes on a compliance checklist. It’s all about creating a safe, secure environment for your employees and protecting your business’s future. By understanding your factory’s unique risks, investing in the best equipment, and maintaining a culture of safety through regular maintenance and training, you can ensure that you’re well-prepared for any fire-related incident.

Remember, in the high-stakes environment of a factory, fire safety is not a place to cut corners. Thoughtful planning, consistent upkeep, and thorough preparation will keep your operations running smoothly and your people safe. Imagine a factory where everyone feels secure, knowing that their safety is always the top priority. That’s the true value of effective fire safety equipment.

Read More Articles:

AFFF Fire Suppression: Applications & Benefits for Enhanced Safety

Fight Fires Eco-Friendly: Rise & Future of Fluorine-Free Foam (ECOFOAM)

Advantages of Advanced AR-AFFF Foam Technology – Fire Protection Ultimate Guide 2024

Related Articles

Protein Foam: Your Guide to Effective Fire Suppression

AR-AFFF Foam: Find the Right Formula for Your Needs

AFFF Foam: Your Essential Guide to Fire Safety

Why ECOFOAM is the Future of Environmentally Friendly Firefighting

Foam Concentrates: Sustainable Solutions for Environmentally Conscious Fire Protection

The Right Foam for Every Fire: Synthetic Concentrates for Varied Hazards & Environments

Expansion Foam Concentrate: The Ultimate Solution for Controlling Flammable Liquid Fires

Stop Fire in Its Tracks: Protein Foam's Versatility Across Hazards & Environments

Fluorine-Free Foam (ECOFOAM): Next-Generation Fire Suppression Solutions for Modern Challenges

Future of Firefighting is Here: Top Trends in Foam Concentrate Technology Explained

Synthetic Foam Concentrates: The Science Behind Superior Fire Control

Expansion Foam Concentrate: The Game Changer for Fighting Large Fires

Protein Foam 101: How It Works to Fight Fires

Advantages of Advanced AR-AFFF Foam Technology - Fire Protection Ultimate Guide 2024

AFFF Fire Suppression: Applications & Benefits for Enhanced Safety

Foam Concentrates vs Traditional Fire Extinguishers: Which is More Effective?

Fight Fires Eco-Friendly: Rise & Future of Fluorine-Free Foam (ECOFOAM)

Synthetic Foam Concentrates: Advancing Fire Suppression with Cutting-Edge Technology

Expand Your Fire Safety Arsenal: Exploring the Versatility of Expansion Foam Concentrate

Protein Foam Concentrates: Harnessing Nature's Power for Effective Fire Suppression | Guide 2024

Advanced AR-AFFF Foam: The Cutting-Edge Solution for Superior Fire Suppression Performance

Understanding AFFF Role in Rapid Fire Suppression

The Rise of Eco-Friendly Fire Suppression: Exploring Fluorine Free Foam (ECOFOAM) Solutions

Foam Concentrates: The Ultimate Guide(2024) to Effective Fire Suppression

Choosing the Right Fire Sprinkler System for Your Commercial Property

Emergency Evacuation Planning: Steps to Ensure Workplace Safety

The Ultimate Guide to Fire Extinguishers: Types, Uses, and Maintenance

The Role of Personal Protective Equipment (PPE) in Firefighting

Keeping Your Business Safe: A Comprehensive Guide to Fire Risk Assessments

Protecting Your Electrical Equipment: The Importance of a Fire Suppression System for Electrical Panels

Protect Your Data Center with a Reliable Fire Suppression System

How to choose a water mist fire extinguisher

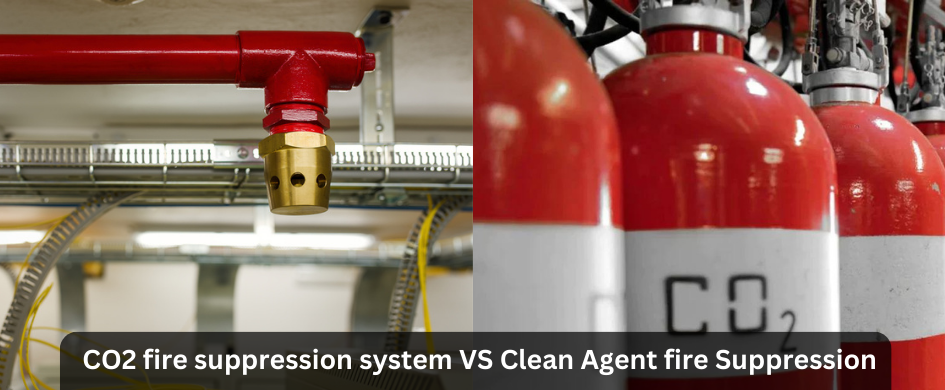

CO2 Fire Suppression System vs Clean Agent fire Suppression

Ensuring Safety in the Factory: Choosing the Right Fire Fighting Equipment

The Top 5 Places Where Fire Suppression Systems are a Must

Difference Between Fire Suppression System and Fire Sprinkler

Ultimate Fire Extinguisher Buying Guide for Business owners

Known and Unknown Facts about Fire Everyone Should Know

Everything you need to know about Water Type Extinguisher

What is a Clean Agent Fire Extinguisher ? Detailed Guide 2024

Everything You Need to Know About Foam-Type Fire Extinguishers

Everything You Need to Know about Dry Chemical Fire Extinguishers - Detailed Guide 2024

Top Fire Extinguisher Manufacturers in India